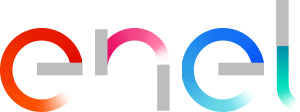

General Information

Preventive Measures undertaken by Gas Atacama

There is strict compliance with national and international guidelines and standards in the design and construction of the gas pipeline.

- Quality of the materials.

- X-ray inspection of 100% of the gas pipeline welding.

- Pipeline cathode protection system (prevents corrosion).

- Pipeline installation considering a minimum depth in accordance with population density.

- Stabilization measures and special works in natural hazard areas (landslides, fault crossing, rivers, etc.).

- Hydraulic testing exceeding the maximum operating pressure.

- Technical Inspection during construction and Project Certification by International Quality Control Companies.

During operation the system is monitored in its entirety, 24 hours per day, 365 days per year.

- Scada satellite monitoring and communications system (remote control from Jujuy (Argentina) and Santiago (Chile).

- Gas pipeline and facility programming and maintenance procedures. Preventive maintenance.

- Study of Natural Hazards and Auditing Processes.

- 24 hour telephone watch.

Regular Controls

- Periodic inspection of the pipeline in order to assess the corrosion conditions.

- Cathode protection controls.

- Valve operation and maintenance controls.

- Water erosion controls.

- Clogging detection.

- Leak detection.

- Step by step tour of the whole gas pipeline.

- Third party activity and human settlement control.

- Community broadcast.

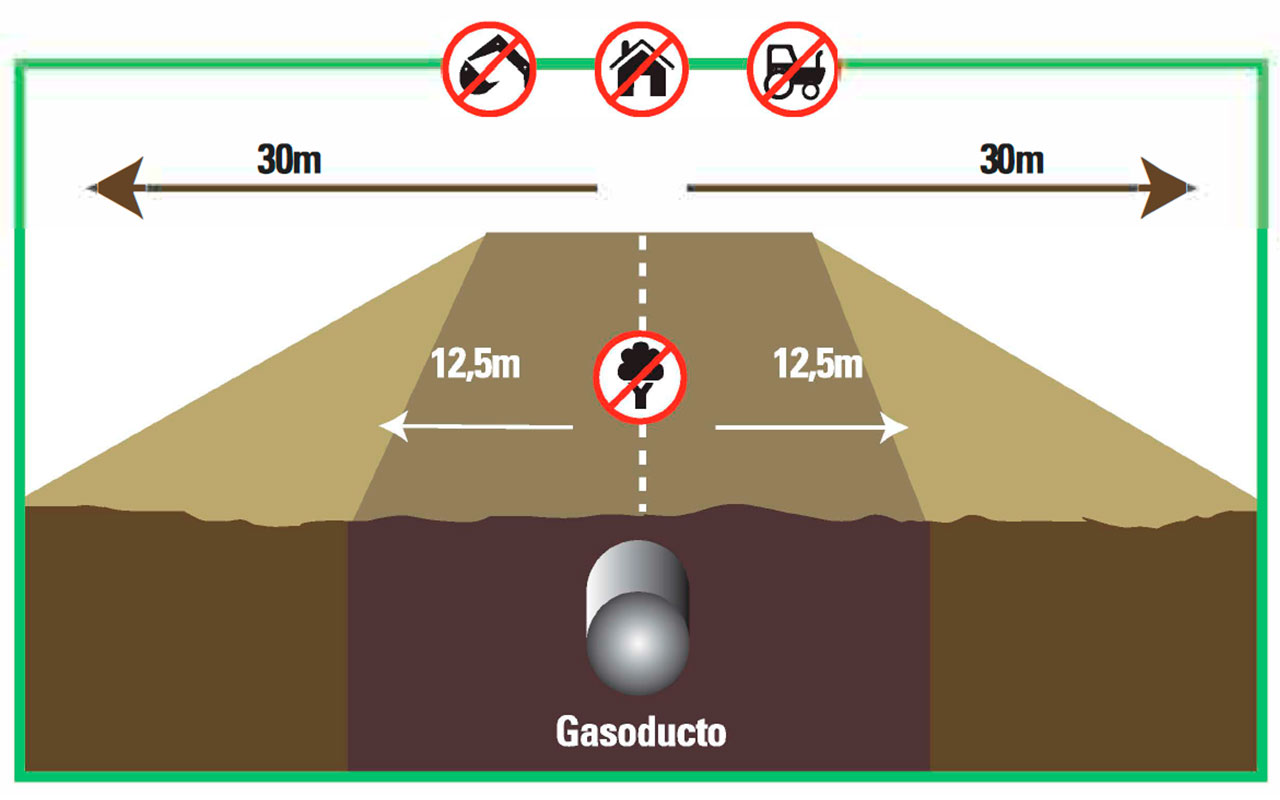

Safety Strip Restrictions

Prohibition of planting trees closer than 12.5 meters distance away from each side of the gas pipeline.

Prohibition of excavating, constructing, making fire, and transiting with heavy machinery less than 30 meters distance away from each side of the gas pipeline.

NOTE: The signs and markings are referential and do not necessarily indicate the exact location and depth of the gas pipeline.